Table of Contents

ToggleOCCUPATIONAL HEALTH HAZARDS

In the field of occupational health, it is important to understand the concept of hazards and risks associated with the workplace. The following definitions and processes help in identifying and controlling these hazards:

- Hazard: A hazard refers to a situation in the workshop that has the potential to cause harm, such as personal injury, disease, or even death.

- Risk: Risk is the probability or chance of a hazard leading to actual injury, disease, or death.

- Hazard identification: This process involves actively identifying all possible situations in the workplace where individuals may be exposed to risks of injury, disease, or death.

- Hazard control: Hazard control entails implementing policies, standards, procedures, and making physical changes to the workplace to eliminate or minimize the adverse risks.

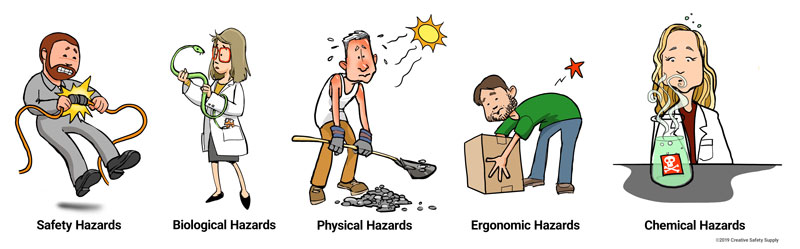

Classification of Workplace Hazards

Workplace hazards can be categorized into different types.

- Physical Hazards: These hazards are associated with physical factors in the workplace, such as noise, vibration, radiation, temperature extremes, and ergonomic stressors. They can cause direct harm to workers’ physical well-being.

- Mechanical Hazards: Mechanical hazards arise from machinery, equipment, or processes that can lead to injuries, such as crushing, cutting, or shearing. Examples include unguarded machinery, faulty equipment, or inadequate machine maintenance.

- Chemical Hazards: Chemical hazards encompass exposure to hazardous substances in the workplace, including toxic chemicals, gases, fumes, or flammable materials. Exposure can occur through inhalation, ingestion, or skin contact, potentially resulting in poisoning, respiratory issues, or chemical burns.

- Biological Hazards: Biological hazards are associated with exposure to living organisms or their byproducts, such as bacteria, viruses, fungi, or parasites. These hazards are common in healthcare settings, laboratories, or agricultural environments, and can lead to infectious diseases or allergic reactions.

- Ergonomic Hazards: Ergonomic hazards arise from work tasks, equipment, or the workplace layout that can cause musculoskeletal disorders or physical strain. Poor posture, repetitive movements, lifting heavy objects, or poorly designed workstations can contribute to ergonomic hazards.

- Psychosocial Hazards: Psychosocial hazards involve factors related to the social and psychological aspects of work. They include stress, work-related violence, bullying, harassment, or excessive workload, which can have detrimental effects on mental and emotional well-being.

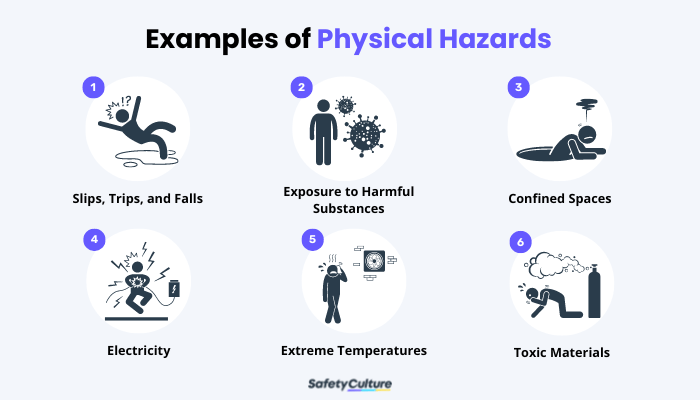

Physical Hazards

Physical hazards in the workplace are associated with elements that can cause harm due to their physical characteristics. Examples of physical hazards include:

- Work at Height: Working at elevated levels without proper fall protection measures.

- Vibration: Exposure to excessive vibrations, such as from handheld tools or machinery, leading to musculoskeletal disorders.

- Noise: Excessive levels of noise that can result in hearing loss or other hearing-related issues.

- Heat: Extreme temperatures in the workplace that can lead to heat stress, heat stroke, or cold stress.

- Trip Hazards: Objects or conditions that can cause individuals to trip and fall, such as uneven surfaces or cluttered walkways. (when you trip or slip but do not actually fall is called near miss)

- Poor Illumination: Insufficient lighting that can lead to reduced visibility and potential accidents.

- Radiation:

a. Non-ionizing radiation:

- Ultraviolet radiation: Exposure in welding, metal cutting, or carbon arc can cause skin erythema, burns, and eye-related issues. Protection with special face shields and goggles is necessary.

- Infrared radiation: Exposure in front of furnaces, steel mills, or glass industry settings can lead to eye and skin problems. Special goggles can provide complete eye protection.

b. Ionizing radiation: Sources include radioactive isotopes and X-ray machines, posing risks such as increased probabilities of certain cancers and cataracts.

Effects of Physical Hazards on Individuals in the Workplace

1. Extreme temperatures:

- Lassitude, irritability, and discomfort.

- Reduced work performance and lack of concentration.

- Heat rash, heat exhaustion, and heat stroke.

2. Noise pollution: Noise-induced hearing loss.

3. Vibration: Vascular disorders in the arms and bony changes in the wrist bones.

4. Radiation exposure: Increased risks of mutation, certain cancers, and cataracts.

5. Poor illumination: Loss of sight due to poor light adaptation.

6. Atmospheric pressure: Increased pressure underwater can cause aseptic bone necrosis around the knee, hip, and shoulder.

7. Occupational exposure to physical factors (e.g., ionizing radiation) can affect reproductive functions, leading to dysfunction, increased incidence of miscarriage, stillbirth, neonatal death, and defects in newborn babies.

Prevention of Physical Hazards

Controls to reduce the risk of slips, trips, and falls include:

- Keeping hallways clear of obstructions.

- Using non-slippery surfaces on stairs or at least on the leading edges.

- Regular maintenance to keep stairs in good repair, ensuring no protruding objects.

- Maintaining proper lighting levels.

- Utilizing angular lighting and color contrast to improve depth perception.

- Educating workers and enforcing the use of proper footwear.

- Promptly cleaning up spills.

- Eliminating tripping hazards such as extension cords.

Keeping walkways free of clutter.

Preventing Electrical Hazards Considerations for using extension cords:

- Protect cords from damage.

- Unplug extension cords when not in use.

- Avoid using damaged extension cords.

- Never modify extension cord plugs.

- Do not chain multiple extension cords together; use a single cord of sufficient length.

Sharp Hazards

- Use safety cutters as bag and box openers.

- Proper storage and disposal of sharp objects like in safety boxes.

Measures to Control Noise in the Workplace:

- Design and maintain machinery to reduce noise levels.

- Segregate and disperse noise sources.

- Use soundproofing materials for floors, walls, and ceilings.

- Rotate workers to minimize exposure.

- Reduce work exposure hours.

- Provide personal protective devices such as earplugs, earmuffs, and helmets.

Control of Exposure to External Radiation Sources:

Control of exposure to external radiation sources rests on three general principles:

- Maintain sufficient distance between the source and workers.

- Minimize time of exposure.

- Implement containment and shielding measures.

- Conduct environmental monitoring and provide alarm systems.

- Perform pre-placement and periodic medical examinations with emphasis on eyes, skin, and blood.

- Provide personal protective clothing.

- Use personal monitoring badges, pocket dosimeters, and whole-body counters.

Chemical Hazards

Chemical hazards are substances that can cause harm due to their chemical composition characteristics. These hazards can exist in the form of gasses or liquids.

Types of Chemical Hazards.

- Asphyxiants: These gasses can cause asphyxia by displacing oxygen or by affecting the respiratory tract system.

- Irritant gasses: Gasses that can cause irritation or inflammation of the mucous membranes upon contact.

- Organo-metallic compounds (e.g., Nickel carbonyl Ni (CO)4): Volatile liquids produced during nickel extraction. Exposure to these compounds can result in hemolysis, anemia, jaundice, and severe cases may lead to anuria.

- Anesthetic vapors: Many of these substances have systemic effects and tend to accumulate in low, poorly ventilated spaces.

- Metals: Examples include lead, mercury, manganese, and arsenic.

- Dust: Fine particles that can be hazardous when inhaled.

Effects of Chemical Hazards

- Silicosis: Caused by inhalation of respirable particles of free crystalline silica.

- Asbestosis: Resulting from the inhalation of asbestos fibers, a material once widely used in building materials.

- Lung cancer: Many chemicals are known to cause lung cancer, including asbestos and some types of silica.

- Chronic obstructive pulmonary disease (COPD): This is a group of lung diseases that cause airflow blockage and breathing difficulties.

- Asphyxiation: Some chemicals can prevent the body from getting enough oxygen, leading to suffocation.

- Systemic intoxication:This is a general poisoning of the body.

- Carcinogens: Chemicals that can cause cancer.

- Irritation: Some chemicals can irritate the skin, eyes, or respiratory system.

- Mutagenicity: Chemicals that can cause mutations (changes) in DNA, which can lead to cancer or other health problems.

Occupational exposure to certain chemicals or physical factors (like ionizing radiation) has been found to have certain effects on reproductive functions:

- Dysfunction in males (sterility or defective spermatozoa) and females (anovulation, implantation defects in the uterus)

- Increased incidence of miscarriage, stillbirth and neonatal death

- Induction of structural and functional defects in newborn babies

Prevention of Chemical Hazards

To prevent chemical hazards, safe work procedures should be implemented:

- Limit the worker’s exposure time.

- Reduce contact with the hazardous substance through any route of exposure.

- Ensure safe disposal of substances and disposable equipment that come into contact with harmful substances.

- Ensure safe handling and decontamination of reusable equipment.

Precautions for potential exposure to noxious gasses include:

- Ventilation of workplaces.

- Provision of gas masks if there is a likelihood of noxious gasses or insufficient oxygen.

- Proper training of workers, working in teams with designated observers at a safe distance.

- Availability of first aid equipment and trained rescuers.

- Prompt removal of affected workers from exposure, providing warmth and rest. Artificial respiration should be administered if breathing stops.

Dust control measures include:

- Segregation of dusty jobs.

- Enclosure of dusty operations.

- General and local exhaust ventilation.

- Proper housekeeping and cleanliness.

- Use of water for dust suppression.

- Personal cleanliness, washing facilities, changing work clothes, separate areas for eating, drinking, and smoking in the case of toxic dust.

- Health education.

- Pre-placement medical examination.

- Use of personal protective equipment.

Mechanical Hazards

Mechanical hazards in the workplace encompass unshielded machinery, unsafe structures, and dangerous, unprotected tools. These factors pose risks to the safety of individuals.

Effects of Mechanical Hazards

- Occupational accidents, primarily due to contact with machinery or tools.

- Bruises on different parts of the body.

- Subcutaneous cellulitis, an infection of the skin and underlying tissues.

Prevention of Mechanical Hazards

- Machine Guarding: Install appropriate guards on machinery to protect workers from moving parts, rotating equipment, and other hazardous components.

- Safety Training: Provide training programs for employees to educate them about the potential mechanical hazards in their work environment. Train them on safe work practices, proper use of tools and equipment, and the importance of following safety protocols.

- Regular Equipment Maintenance: Establish a regular maintenance schedule to inspect and maintain machinery and equipment. This includes checking for wear and tear, loose parts, and any potential hazards. Promptly address any identified issues to prevent accidents.

- Personal Protective Equipment (PPE): Ensure that appropriate PPE, such as gloves, safety glasses, hard hats, is provided to workers. Train employees on the correct use and maintenance of PPE and enforce its consistent usage.

- Hazard Identification and Risk Assessment: Conduct regular hazard assessments to identify potential mechanical hazards in the workplace.

- Safe Work Practices: Establish and enforce safe work practices and standard operating procedures (SOPs) for tasks involving machinery and equipment. These practices should include guidelines for proper use, maintenance, and storage of tools and machinery.

- Emergency Preparedness: Develop and communicate emergency procedures in the event of mechanical hazards, such as equipment malfunctions or unexpected incidents. Ensure workers are aware of emergency exits, evacuation routes, and emergency contact information.

- Regular Inspections: Conduct routine inspections of work areas to identify potential mechanical hazards. Encourage workers to report any hazards or concerns they observe and address them.

- Employee Engagement(Safety Culture): Foster a culture of safety by involving employees in the identification and resolution of mechanical hazards.

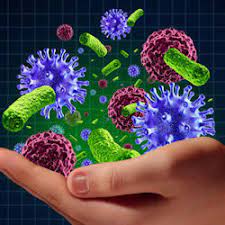

Biological Hazards

Biological hazards involve viruses, bacteria, fungi, parasites, or any living organisms capable of causing diseases in humans.

Transmission of Biological Hazards

- Inhalation: Breathing in airborne pathogens.

- Injection: Entry of pathogens through puncture wounds or contaminated sharps.

- Ingestion: Swallowing pathogens through contaminated food, water, or objects.

- Contact with the skin: Direct contact with infected materials or surfaces.

Effects of Biological Hazards

- Infections: Contracting diseases caused by pathogens.

- Diseases: Developing specific illnesses due to exposure to biological hazards.

- Reduced productivity at work: Illnesses can result in decreased work performance and absenteeism.

- Disability: Severe cases of diseases caused by biological hazards can lead to long-term impairments.

The Contract of Biohazard: The severity of exposure to biological hazards depends on:

- The concentration or number of organisms present in the environment.

- The virulence of these organisms, which refers to their ability to cause disease.

- The susceptibility of the individual to the pathogens.

- Concurrent physical or chemical stresses in the environment, which can enhance the effects of biological hazards.

Ergonomic Hazards

Ergonomic hazards refer to the stress and strain placed on the body through posture and movement, such as frequent repetitive handling of small boxes.

Ergonomics, also known as human engineering or human factors, focuses on designing machines, products, and systems to maximize the safety, comfort, and efficiency of the people who use them.

The ergonomics triad emphasizes that for work to be safe and efficient, the worker/human, the task, and the environment should be in harmony. By considering these three elements in combination, ergonomics aims to optimize the interaction between workers and their work settings, which can lead to increased productivity, reduced risk of injuries, and enhanced well-being for employees.

Principles of Ergonomics

There are 10 fundamental principles of ergonomics which are:

1. Work in neutral postures

- Proper posture maintenance is necessary

- Working too long with “C” curve can cause strain

- Keeping the proper alignment of neck hands wrist are also necessary

2. Reduce excessive force

- Excessive pressure or force at the joints can cause injury

- Better to minimize the work that requires more physical labor

3. Keep everything in reach

- Keeping everything in reach would help in avoiding unneeded stretching and strain

- More or less this principle is related to maintaining good posture.

4. Work at proper height

- Working at right makes things way easier

- Sometimes height can be maintained by adding extensions or avoiding extensions on the chair or tables

5. Reduce excessive motions

- Repetitive motion needs to be avoided

- This can cause disorder and numbness in long run

- Motion scan be reduced by the use of power tools

6. Minimize fatigue and static load

- Fatigue is common in strenuous work

- Having to hold things for longer period is example of static load

- Fatigue can be reduced by the intervals and the breaks between the works.

7. Minimize pressure points

- One needs to be aware of pressure points

- Almost everyone has to sit on chairs that have cushioning, one of the pressure points is behind the knees, which happens if air is too high or when you dangle your legs. Pressure point is also created in between your thigh and the bottom of a table when you sit.

- Anti-fatigue mats or insole can be used

8. Provide clearance

- Work area should have enough clearance

- Let the worker not worry about the bumps that they have to encounter on a daily basis.

9. Move, exercise and stretch

- Move and stretch when you can

- It better to take intervals between the works and stretch and move along

- Stretching technique may differ and depend on the work one does

10. Maintain a comfortable environment

- This principle is focused on the other components of the working environment.

- It is concerned about lightning, space, cool air and many more.

Causes of Ergonomic Hazards

Many ergonomic problems arise from technological changes or poorly designed job tasks. The following conditions can contribute to ergonomic hazards:

- Repetitive Motions: Performing the same motion repeatedly, like typing or using a mouse, can strain muscles, tendons, and nerves.

- Awkward Postures: Maintaining uncomfortable positions for extended periods, such as reaching overhead or bending at the waist, can cause muscle imbalances and pain.

- Forceful Exertion: Applying excessive force, such as lifting heavy objects or using tools with high resistance, can lead to injuries like muscle strains and tendonitis.

- Static Posture: Holding the same position for long periods, like sitting at a desk or standing in one spot, can restrict blood flow and cause discomfort and pain.

- Vibration: Exposure to excessive vibration, like from using power tools or operating machinery, can damage nerves, tendons, and bones.

- Improper Workstation Design: Workstations that are not properly designed to fit the individual worker’s needs can contribute to many ergonomic hazards. This includes factors like desk height, chair adjustments, and monitor placement.

- Poor Lighting: Inadequate or improper lighting can strain the eyes and lead to headaches and fatigue.

- Insufficient Work Breaks: Lack of adequate rest breaks allows fatigue to build up, increasing the risk of injury.

- Heavy Lifting: Lifting heavy objects improperly or frequently can put strain on the back, shoulders, and knees.

- Lack of Training: Employees who are not properly trained on how to perform their tasks safely and ergonomically are more likely to be exposed to hazards.

Repetitive motions or shocks over prolonged periods, such as those involved in jobs like sorting, assembling, and data entry, can lead to irritation and inflammation of the tendon sheath in the hands and arms, known as carpal tunnel syndrome.

Effects of Ergonomic Hazards

- Tenosynovitis: This condition affects the tendons and the sheaths that surround them. Repetitive motions, especially those involving the wrist and hand, can cause inflammation and pain within the tendon sheath. This can lead to stiffness, swelling, and difficulty moving the affected area.

- Bursitis: This involves inflammation of the bursa, a fluid-filled sac that cushions and lubricates joints. Ergonomic hazards like repetitive motions, awkward postures, and forceful exertion can irritate the bursa, causing pain, swelling, and tenderness.

- Carpal Tunnel Syndrome: This condition occurs when the median nerve, which runs through the carpal tunnel in the wrist, is compressed. Repetitive hand movements, awkward postures, and prolonged pressure on the wrist can all contribute to this nerve compression, leading to numbness, tingling, and weakness in the hand and fingers.

- Raynaud’s Syndrome (“White Fingers”): This condition affects blood circulation in the fingers, causing them to turn white, then blue, and finally red. Exposure to cold temperatures and vibrations can trigger Raynaud’s syndrome, often seen in workers who operate vibrating tools or work in cold environments.

- Back Injuries: Ergonomic hazards like poor posture, heavy lifting, and repetitive bending can strain the muscles, ligaments, and discs in the back. This can lead to pain, stiffness, and even herniated discs.

- Muscle Strain: Overusing muscles or straining them through awkward postures can lead to muscle strain, resulting in pain, tenderness, and limited range of motion. This is common in workers who perform repetitive tasks or lift heavy objects improperly.

Prevention of Ergonomic Hazards

To prevent ergonomic hazards, the following control measures should be implemented:

1. Ergonomic Design & Engineering:

- Workstation Optimization: Design workstations with adjustable heights, comfortable seating, and proper monitor placement to promote neutral postures and minimize strain.

- Equipment Selection: Choose tools, equipment, and furniture that are ergonomically designed to reduce strain and fatigue. This includes computer workstations, chairs, and lifting devices.

- User Input: Involve workers in the selection and testing of new equipment to ensure it meets their needs and reduces ergonomic risks.

2. Work Practices & Training:

- Proper Lifting Techniques: Provide training on safe lifting techniques to minimize back strain and injuries. Encourage the use of lifting aids for heavy objects.

- Task Rotation: Rotate workers among different tasks to avoid prolonged exposure to repetitive motions or static postures.

- Work Breaks & Rest: Encourage frequent breaks to stretch and move around, reducing muscle fatigue and stiffness.

- Ergonomics Education: Train workers to recognize biomechanical risk factors, understand the signs and symptoms of ergonomic injuries, and implement safe work practices.

3. Administrative Controls:

- Work Shift Scheduling: Optimize work schedules to minimize extended work hours and overtime, reducing the risk of fatigue-related injuries.

- Workload Management: Ensure workloads are manageable and avoid excessive demands that could lead to ergonomic hazards.

- Job Design: Evaluate tasks and consider alternative methods to minimize repetitive motions, awkward postures, and forceful exertions.

4. Personal Protective Equipment:

- When Necessary: Provide and mandate the use of personal protective equipment (PPE) when it can help prevent injuries, such as gloves for tasks involving vibrations or hand tools.

5. Continuous Improvement & Monitoring:

- Self-Assessments: Provide workers with self-assessment tools to identify potential ergonomic hazards in their work areas.

- Regular Reviews: Conduct periodic ergonomic assessments of workplaces, work processes, and equipment to identify areas for improvement.

- Incident Reporting: Encourage workers to report any incidents or discomfort related to ergonomic hazards. This data can be used to make adjustments and improve safety.

Ergonomics, or the proper design of work systems based on human factors, offers several advantages, including more efficient operations, fewer accidents, reduced training time, lower operational costs, and more effective use of personnel.

Psychosocial Hazards

Psychosocial hazards are factors in the workplace that can cause psychological stress and strain on individuals.

These hazards have become more prevalent in recent years, with issues such as time pressure, hectic work environments, and the risk of unemployment contributing to psychological stress. Jobs with heavy responsibility, monotonous work, and constant concentration requirements can also have adverse psychological effects.

Types of Psychosocial Hazards

- Poor vocational guidance: Lack of clear career paths, training opportunities, or support for professional development can lead to frustration and demotivation.

- Poor arrangement of working hours: Inconsistent or unpredictable schedules can disrupt sleep patterns and contribute to work-life imbalances.

- Poor job design and work methods: Repetitive, monotonous tasks, lack of autonomy, and unclear job responsibilities can contribute to burnout and dissatisfaction.

- Poor management: Lack of support, unclear expectations, ineffective communication, and inconsistent leadership styles can create a stressful and toxic work environment.

- Abusive patients: Exposure to aggressive or abusive patients can lead to emotional distress and stress for healthcare workers.

- Long working hours: Excessive work hours without adequate breaks can lead to fatigue, stress, and burnout

- Sexual harassment: Unwanted sexual advances, requests for sexual favors, or other verbal or physical harassment based on sex can create a hostile work environment.

- Workplace violence: Threats, harassment, or physical violence in the workplace can create a climate of fear and anxiety.

- Unfriendly work shifts: Such as chronic night duties can lead to stress.

- Technostress: The constant pressure to keep up with new technologies, manage a growing volume of information, and remain connected can lead to stress and burnout

- Substance abuse as a response to excessive workplace stressors

- Work-Life Conflict: Balancing work demands with family responsibilities and personal commitments can lead to stress and anxiety.

- Exposure to Stressors: Noise, poor air quality, and other environmental factors can contribute to stress and affect mental well-being.

- Exposure to poor indoor air quality that induces stress

Control Strategies for Psychosocial Hazards Work Shift Issues

- Engage workers in the design and planning of shift schedules.

- Avoid scheduling demanding, dangerous, or monotonous tasks during the night shift, especially during early morning hours when alertness is lowest.

- Limit permanent night shifts and offer a choice between permanent and rotating shifts.

- Use forward-rotating schedules for rotating shifts when possible.

- Arrange shift start/end times to correspond to public transportation or provide transport for workers on specific shifts.

- Limit shifts to a maximum of 12 hours (including overtime) and consider the needs of vulnerable workers.

- Limit night shifts to 8 hours for demanding, dangerous, or monotonous work.

- Encourage regular breaks away from the workstation and discourage saving up break time for the end of the workday.

- Limit consecutive working days to a maximum of 5-7 days.

- Limit consecutive shifts to 2-3 days for long work shifts, night shifts, and shifts with early morning starts.

- Design shift schedules to ensure adequate rest time between successive shifts.

- Provide a minimum of 2 nights’ full sleep when switching from day to night shifts.

- Incorporate regular free weekends into the shift schedule.

Technostress (Stress Resulting from New Technologies)

- Select user-friendly technology.

- Involve workers in technology selection, trial, and implementation, and gather feedback on its use.

- Provide sufficient training to ensure workers feel confident and competent in using the technology.

Work-Life Balance and Reduction of Excessive Workloads

- Offer flexible time arrangements, such as alternative work schedules, compressed work weeks, reduced hours/part-time work, and phased retirement.

- Allow flexible work locations through telecommuting and satellite offices.

- Implement flexible job design through job redesign and job sharing.

- Provide wellness programs.

- Offer flexible benefits including paid and unpaid leaves for maternity, parental care, education, and sabbatical.

- Support employer-sponsored childcare and eldercare services.

Workplace Violence

- Establish management policies and procedures with a zero-tolerance approach to violence or abuse.

- Provide worker education on violence awareness, avoidance, and de-escalation procedures.

- Establish liaison and response protocols with local police.

- Enable workers to request support.

- Offer counseling services.

Work-Related Stress

- Provide training to increase awareness of signs and symptoms of critical incident stress.

- Establish a critical incident stress team to respond to incidents, with clear communication and call procedures.

Work-Related Substance Abuse

- Provide problem-solving resources and support for workers.

- Involve workers in the development of substance abuse policies and procedures.

- Educate workers about substance abuse.

- Implement procedures to limit individual access to narcotics.

- Offer counseling services and return-to-work plans.

Conditions Likely to Be Sources of Workplace Hazards

- Ensure proper access routes, such as ramps.

- Address hazardous tasks in the workplace, such as repetitive lifting of patients.

- Ensure correct installation and use of equipment/machines.

- Maintain and repair equipment adequately.

- Address exposure to hazardous substances, such as blood and other body fluids.

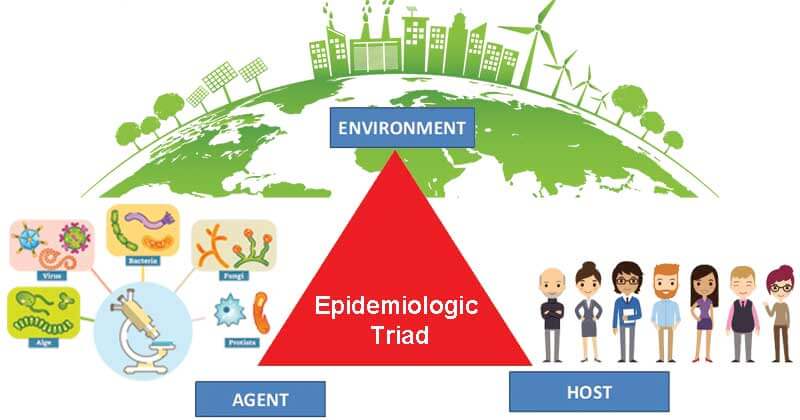

The Epidemiologic Triangle

The Epidemiologic Triangle is a model that helps us understand infectious diseases. It has three parts:

- Agent: The microbe that causes the disease.

- Host: The organism that is infected with the disease.

- Environment: The surroundings that allow the disease to spread.

Agent

The agent is the cause of the disease. When studying the epidemiology of most infectious diseases, the agent is a microbe—an organism too small to be seen with the naked eye. Disease-causing microbes are bacteria, viruses, fungi, and protozoa (a type of parasite).

- Bacteria: Single-celled organisms that can reproduce themselves.

- Viruses: Tiny particles that contain genetic material but cannot reproduce on their own.

- Fungi: Multicellular organisms that live off other organisms.

- Protozoa: Single-celled organisms that live off other organisms.

Host

The host is the organism that is infected with the disease. The host can be a human, animal, or insect. The host’s immune system plays a role in determining whether or not the disease will develop.

Environment

The environment includes the physical surroundings, such as temperature and humidity, as well as the presence of other organisms. The environment can also play a role in the spread of disease. For example, mosquitoes can transmit malaria, and contaminated water can transmit cholera.

Conclusion

The Epidemiologic Triangle is a useful tool for understanding how infectious diseases spread. By understanding the three parts of the triangle, we can better prevent the spread of disease.

Here are some additional points to consider:

- The Epidemiologic Triangle can be used to understand a variety of infectious diseases.

- The three parts of the triangle are interconnected.

- By breaking one of the links in the triangle, we can help to prevent the spread of disease.

Love it

this is amazing wow!